Deepsea titanium pressure hulls

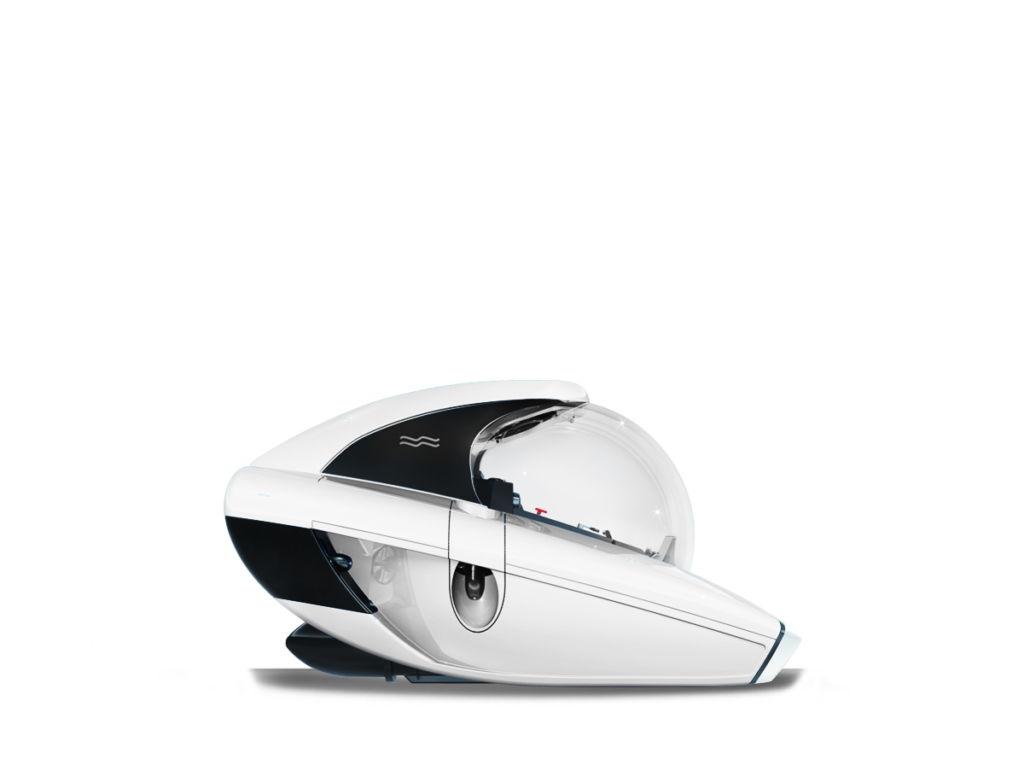

The Pressure Vessel for Human Occupancy (PVHO) is at the heart of each U-Boat Worx submersible. It allows passengers to explore the subsea realm in safety and comfort without the risks associated with SCUBA diving. Across our range of submarines, we have subs where the entire pressure hull is made of acrylic; whereas other models have a high-grade steel section combined with a large acrylic window.

In our deepest-diving submersibles, we use titanium alloys to achieve optimum size, weight and performance characteristics.

Titanium has several distinct advantages – it is stronger than regular steel thereby enabling us to keep the weight of deep-diving models as low as possible. Other advantages include that it requires no maintenance, has an extended lifecycle, and has incomparable anti-corrosive properties.

So how do we make these titanium sections for the deep-diving models? Every component starts at the drawing board, where we conduct feasibility studies. With the help of advanced FEA (Finite Element Analysis) software, we calculate how thick the titanium needs to be to withstand pressure at depth – including an immense safety factor. We also determine how best to connect metal components to the acrylic windows.

After approval of world-leading classification society DNV GL, the titanium alloy needs to be specially produced. All materials are subject to rigorous quality tests before being processed. The titanium is forged, which takes place under a vacuum to ensure highest quality and purity. After further material and weld tests, various titanium parts that make up the pressure hull are welded. DNV GL also oversees and scrutinizes all welding procedures to ensure safety.

Upon completion of the welding, every join gets x-rayed for inspection. The end result is subject to further testing and examination. Once the titanium components are ready, the acrylic windows are installed to complete the pressure vessel.

The complete pressure vessel then undergoes a hydrostatic pressure test that simulates multiple dives – all deeper than the designated maximum operating depth of the submarine. Only after successfully completing these stringent safety tests, the interior, diving tanks, and other components will be installed to complete the submersible.